Custom, Spot, Brand, and Pantone colors are all examples of custom single printing ink colors other than Cyan, Magenta, Yellow, or blacK. Just like CMYK inks, they filter (subtract) light that is reflected from the substrate.

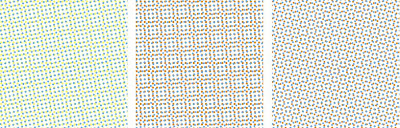

On the left below is a patch of color created with 4/C process screens and on the right the same color using a single custom ink.

On the left below is a patch of color created with 4/C process screens and on the right the same color using a single custom ink.

Custom colors are typically specified using one or more of the following:

1- a reference physical sample such as a swatchbook, color chip, or physical sample

2- a numeric value that references a swatch or color guide book

3- a formula or recipe to mix ink ingredients in order to achieve the custom color

4- a numeric value that references a color model such as CIE L*a*b*

The Pantone reference swatchbook for its proprietary custom colors, contains a numeric color reference number, sample swatches of the custom color, as well as formulae for mixing inks to achieve the selected color.

Note: There are no specific color tolerances defined by Pantone as to what constitutes an acceptable match when variation naturally occurs.

Note: There are no specific color tolerances defined by Pantone as to what constitutes an acceptable match when variation naturally occurs.

The corporate brand color reference swatchbook below, mimics Pantone's but adds acceptable "High/Low" reference samples to accommodate ink density variations that occur naturally in presswork.

The primary brands of proprietary custom color systems are:

Pantone, the dominant spot color specification system in the United States and Europe.

Toyo, a popular spot color system that is used in Japan.

DIC, Dainippon Ink & Chemicals, Inc., another common Japanese spot color system

ANPA a palette of 300 colors specified by the American Newspaper Publishers Association for spot color usage in newspapers

HKS Hostmann-Steinberg Druckfarben, Kast + Ehinger Druckfarben und H. Schmincke & Co. containing 120 spot colors and 3250 tones for coated and uncoated paper

The hues for all these proprietary colors are defined using name, ink mix formula, and (not always published) CIE L*a*b* values.

Aspects of the Pantone spot color system

Custom colors are not limited by the gamut constraints imposed by monitor displays or press gamuts that depend on CMYK primaries. About 95% of all Pantone spot colors are within monitor gamut, while only about 34% of Pantone spot colors are within the standard CMYK gamut.

This short video (click on the "play" arrow) shows 1113 Pantone colors (excluding metallics and fluorescents) plotted against the GRACoL7 CMYK gamut. Only 376 PMS colors (33.8%) are actually within gamut for four color process (at 175 lpi) printing.

The Pantone GOE color library is very similar to the original Pantone spot color library in that respect since most of the GOE colors fall between the original Pantone colors.

The Pantone spot color library was never designed, nor intended, to be used as a way to specify colors that will be printed using 4/C process CMYK. As a result, because of the gamut differences mean that 4/C process simulations of the Pantone library will, can only provide an approximation and in the majority of cases, deliver disappointing results.

At left a 4/C simulation of the Pantone spot ink color at right.

Some key notions:

1- The CMYK recipes for Pantone spot colors are generic approximations. They do not reflect regional print color standards, nor individual printshop color.

2- Approximately 66% of the library is out of gamut for 4/C process.

3- The specific colors in the library are based on ink mixing formulae - not target CIEL*a*b* color values. The CIEL*a*b* color values included with some applications, e.g. Adobe Photoshop, are only included as a courtesy to assist with conversion to CMYK – they are not the target for the color itself.

4- The Pantone Goe library is not intended to replace PMS but to supplement it (PMS library is ~1089 colors vs Pantone Goe’s 2,058). Pantone Goe spot colors are primarily “’tween” colors and about 400 colors overlap with the original Pantone spot colors.

5- There are no published specifications for acceptable variation of a Pantone spot color due to natural variation on press. Each printer/specifier/customer must determine their own color tolerance specifications.

6- The RGB values in the GOE swatchbook are actually sRGB values-I.e. not a typical printing color space.

Custom/Spot colors in the pressroom 1-

1- CMYK inks are formulated to ISO specifications - there are no ISO Spot ink specifications. This may cause variations in the final color when the inks are prepared at different geographic locations.

2- CMYK inks are designed to overprint (wet trap) - Spot color inks designed to print isolated (dry trap). This can cause unexpected results with overprinting unless they have been specifically custom formulated to wet trap.

3- CMYK inks are transparent - Spot inks are typically semi-opaque.

4- CMYK inks have defined density (ink film thickness), dot gain and trap targets - there are none for Spot color inks.

5- Pantone spot colors are generally not formulated to be halftone screened. Some colors, as a result of the pigment grind used may appear grainy, especially with high lpi AM/XM and FM screens. If the custom spot color ink will be screened, it is best to confirm with the ink supplier that the ink formulation is suitable.

6- Pantone spot colors are often not mixed by the ink vendor, or printer, using the actual official Pantone base colors. This may cause color shifts due to the different spectral qualities of the base inks used (metamerism). To help ensure color consistency when printing at different locations, try to make sure that the base inks used to create the custom color are the same and from the same ink vendor.

7- Spot color inks are typically multi-pigment which may cause unexpected color shifts under different lighting conditions (metamerism).

8- Because of their ink composition, some custom spot colors may shift dramatically when heat is applied or when laminated. Always test before using on a live job.

9- Ink draw-downs, or pulling samples of ink on paper, tests the color of an ink mixture by spreading a thin film of ink on paper with a spatula or by using a tiny tabletop press, generically called a "Little Joe," that holds a 4×6´´ offset printing plate.

By using real ink on the paper intended for the job, users get a good prediction of how that ink will look on the actual substrate, allowing adjustments in color and paper selection well before press time. However, since the tabletop press does not use water, as is used on the proper offset press, there can be subtle differences in how the spot color will actually look in the final presswork especially if the spot color will be halftone screened.

Some best practices and tips – primarily for designers and brand owners 1-

1- Wherever possible use/insist on Pantone/Goe base inks to mix Pantone spot colors.

2- When developing custom/brand colors, it is best to use CMYK inks that conform to ISO 12647-2 as the primary base colors. Although this reduces the range of possible hues, it will allow 4/C process printing to simulate the spot brand color accurately in print applications where the spot color cannot be used.

3- When developing custom/brand colors make sure that the ink formulae contain information about the ink vendor of choice.

4- Formula-based custom/brand colors should include reference CIE L*a*b* values. The CIE L*a*b* values should be the target for color and take priority over sample swatches.

5- Custom/brand colors should include a specification for acceptable defined with either a high/low density range or a CIE L*a*b* DeltaE value. Providing a swatch guide with holes through it as in this example:

allows users to place the swatch over the press sheet to more easily confirm the color match.

6- RGB values associated with custom/brand colors should specify the source (e.g. sRGB, Adobe 1998, etc)

7- Beware of the effects of optical brighteners used in paper. If proofing paper and final substrate don’t have equal level of optical brighteners then color will probably not align between them - especially in pastel spot colors.

8- The amount of optical brighteners, as can be seen in the below image taken under blacklight, that is used in the Pantone GOE guide (at left in the below image) is higher than in the standard Pantone swatch book (at right below):

Because optical brightening agents can fade quickly under normal lighting conditions, this may reduce the integrity of the colors displayed in the GOE guide more quickly than the standard Pantone swatchbook. Therefore, store swatchbooks away from light.

9- The "white" ink used in pastel Pantone and other custom colors is essentially a varnish. As such it will yellow with age and cause a color shift.

10- The only proof of presswork is actual presswork - all off-press proofs share some degree of compromise - especially when proofing spot colors. Press proof whenever possible - especially when the spot colors will be halftone screened. Include any special finishing (e.g. coatings and lamination). Always clarify whether spot colors represented on proofs are valid for color or just place holders. Treat draw-downs of spot color screen tints with skepticism. Treat inkjet proofs of spot screen tints with suspicion and proofs showing spot color overprints with humor.

I think that most of us have been hit with an unpleasant surprise when a Pantone ink color shifts after being UV or aqueous coated. As one example, Reflex Blue (arguably the most difficult color in printing) prints as dark blue but will dry with a reddish sheen that will not dry properly. To try and make it dry faster the printer might run it through the press a second time to apply a coating, either UV or Aqueous, to seal the ink. This causes an immediate color shift which will continue to shift over the course of a few days.

I think that most of us have been hit with an unpleasant surprise when a Pantone ink color shifts after being UV or aqueous coated. As one example, Reflex Blue (arguably the most difficult color in printing) prints as dark blue but will dry with a reddish sheen that will not dry properly. To try and make it dry faster the printer might run it through the press a second time to apply a coating, either UV or Aqueous, to seal the ink. This causes an immediate color shift which will continue to shift over the course of a few days. In order to avoid the costs involved with reprinting a spoiled job, when mixing and/or specifying PMS colors it's critical to inform your ink vendor that you will be aqueous or UV coating the job.

In order to avoid the costs involved with reprinting a spoiled job, when mixing and/or specifying PMS colors it's critical to inform your ink vendor that you will be aqueous or UV coating the job.