Most printers with CtP output use tone calibration curves applied to their plates in order to achieve the print characteristic they've targeted for their shops. Many shops will have multiple curve sets to accommodate different paper characteristics, screening, or solid ink density targets. As a result, making sure that the correct curve has been applied is an important part of the plate imaging quality control process.

Most printers with CtP output use tone calibration curves applied to their plates in order to achieve the print characteristic they've targeted for their shops. Many shops will have multiple curve sets to accommodate different paper characteristics, screening, or solid ink density targets. As a result, making sure that the correct curve has been applied is an important part of the plate imaging quality control process.This technique creates an inspection target that will be imaged in the gripper area of the plate. It will allow prepress to quickly confirm visually that the correct curve has been applied without having to measure the plate.

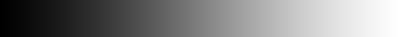

1- In PhotoShop create a new grayscale image 3,300 x 600 pixels at 300 dpi. Instead of 600 pixels, you can use a height one half the height available in the gripper area.Then create a 100% black to 0% white gradient ("dither" should be deselected):

2- Apply the "Equalize" adjustment to the gradient: "Image"-->"Adjustments"-->"Equalize" This linearizes the gradient.

3- Posterize the gradient "Image"-->"Adjustments"-->"Posterize" Enter "21" for the levels value. This divides the gradient into 5% tone increments.

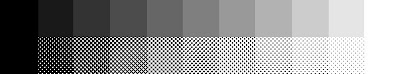

4- Make a copy of this gradient and send it through your workflow so that it is halftone screened with the calibration curve you wish to use:

This screened bitmap with curve applied needs to be captured from your workflow as an image. If you cannot capture a bitmap from your workflow you may need to call on your workflow vendor's demo facility or customer support to do this for you.

This screened bitmap with curve applied needs to be captured from your workflow as an image. If you cannot capture a bitmap from your workflow you may need to call on your workflow vendor's demo facility or customer support to do this for you.5- Impose the screened gradient with the original posterized linear gradient.

6- When this graphic is imaged to plate the screened bitmap is untouched by the workflow since it is a bilevel bitmap containing no grey levels. However, the greyscale continuous tone part of the graphic will be affected by the calibration.

If the correct curve has been applied you'll see no difference in the top and bottom part of the graphic:

If no curve, or the wrong curve, is applied you'll easily see the difference in the tones in the graphic:

If no curve, or the wrong curve, is applied you'll easily see the difference in the tones in the graphic:

This target assumes that the same curve is being applied to all plates in a CMYK job. If individualized curves are applied to separate CMYK channels then copy the posterized linear gradient into each channel of a blank CMYK image that is the same size as the gradient. Then send it through the workflow applying the plate curves, capture the screened bitmaps, recombine them into a single CMYK image file and finally combine it with the original CMYK graphic as was done with the greyscale graphic.

It can help if the screened bitmap image included the name of the applied calibration curve as a further way to ensure that the correct curve(s) were being applied.

If there is no room in the gripper to stack the gradients, you can integrate them by combining the screened bitmap into the greyscale gradient like this:

The result is the same. The correctly applied curve would make the graphic appear like this:

The result is the same. The correctly applied curve would make the graphic appear like this: While the wrong calibration curve would make the graphic appear like this:

While the wrong calibration curve would make the graphic appear like this:

No comments:

Post a Comment